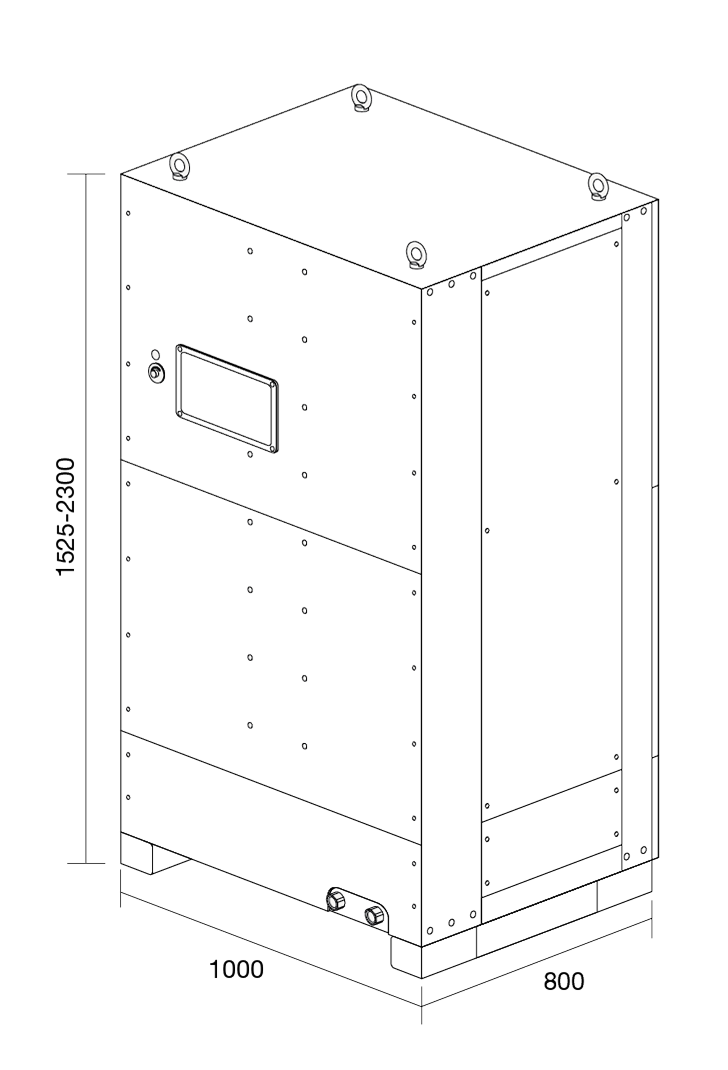

Modular full-bridge switch-mode rectifier with a 3-phase input and floated output poles, the largest in our Vega lineup. It can house 15 power modules to deliver up to 360 kW of output on a small footprint. All modules work in parallel for enhanced reliability and easily serviced from the front. The V802 can be interconnected with other rectifiers for increased power for the most power-demanding applications. It is built on a footprint of only 1000mm by 800mm and its design facilitates back-to-back and side-by-side installations to maximize power density. It comes in air- or water-cooled version with an optional heat exchanger to isolate the internal loop from the customer circuit and regulate the internal temperature and prevent condensation. Manual or automatic control is possible, which allows programming of waveforms, monitoring Ah, and more. A bipolar synchronized rectification enables each module to reverse its output and produce pulsed waveforms with excellent efficiency.

V820 CABINET

AIR AND WATER COOLED

UP TO 22,5 kA

- Multiple configurations of modules and CPUs in one cabinet

- Installation side by side or back to back

- Modules and CPUs service from the front

- Optional water-water heat exchanger

- Optional front door

- Reverse polarity (on each module)

- Floating output poles

| MAIN VOLTAGE (3 PHASE) | 208 / 230 / 400 / 440 / 480 / 575 VAC ± 10% / 50 - 60 Hz |

| MAX. OUTPUT POWER | 168 kW |

| MAX. OUTPUT VOLTAGE | 6 - 400 VDC |

| MAX. OUTPUT CURRENT | 100 - 10500 A DC |

| CURRENT RIPPLE | <3% (<1% on request) |

| OPERATION MODE | Current or voltage control |

| CURRENT REGULATION RANGE | 2 - 100% |

| VOLTAGE REGULATION RANGE | 5 - 100% |

| ACCURACY | 1% of full scale |

| POWER FACTOR | >0.92 @@ rated load |

| EFFICIENCY | 89 - 94% @@ rated load |

| COLOR | RAL 3004 |

| COOLING | Air and Water |

| DEGREE OF PROTECTION | IP31 Air cooled IP42 / IP54 Water cooled |

| WEIGHT | 528,5 kg - 950 kg |

| AMBIENT TEMPERATURE | 40ºC (up to 50ºC on request) |

| INPUT WATER COOLING TEMPERATURE | 19 - 35ºC |

CABINET OPTIONS

WWHE

Internal water cooling circuit capable of temperature regulation to prevent condensation in the system. It is isolated (no water mixing) with a copper-clad water-water heat exchanger.

WMAT

Nickel-clad option for the WWHE to improve its corrosion resistance.

DOORS

Panel doors that open 180 degrees.

FEET

Steel 100mm (4”) support.

AC ON TOP

AC input moved to the top of the rectifier.

INLET ON TOP

Communication input wired from the top front of the rectifier.

PANELS

Side panels that allow two cabinets to be joined back to back.

7.0” HMI

—

GENERAL OPTIONS

OPERATING TEMP

Operating ambient temperature up to 50°C with derating.

•

•

DC HIGHER EFF

Improved efficiency by utilizing synchronous rectification technology to minimize losses. Modules under 16V can see efficiency gains of up to 6 percentage points. These benefits can also be seen with higher voltage modules operating at lower voltages, improving the full range of the efficiency curve.

•

•

REVERSE POLARITY

Allows switching the output between forward and reverse polarity.

•

•

1MS PULSE

This function is available when rise and fall times faster than 1 second are critical for the production process. Done by a combination of software and a selection of electrical components. Recipe patterns can be followed by controlling the CPU to achieve a rise time and fall time of 1ms with no overshoot when using resistive loads.

•

•

AUX POWER FOR THE CPU

An input to supply power directly to the CPU that enables continuous communication and monitoring in case the primary power is disconnected. A 24 Vdc input is included; an added internal power supply is required if a single-phase input is needed.

•

•

LOWER RIPPLE

Reduces the DC ripple to < 1%.

•

•

UL COMPLIANCE

Certain components are changed to meet UL standard compliance.

•

•

E-STOP

The E-Stop system can be configured to cut the output power of the rectifier. Complies with international standards IEC 62061 SIL Level 3 Protection and ISO 13849-1 Protection Level E. The E-Stop of rectifiers can be interconnected for simultaneous emergency activation when necessary to ensure operational safety. The E-Stop can be activated by peripheral devices when emergency conditions are detected. It is possible to configure for automatic or controlled reset.

•

•

COMM. PROTOCOLS

A wide range of industrial communication standards via a certified HMS AnyBus IC. Communication protocols are not CPU software dependent and are interchangeable with ease. The Data Map structure is not communication protocol dependent, allowing for simplified system integration. Optional communication protocols: Profibus-DP, DeviceNet, EthernetIP, Profinet, Modbus-TCP.

•

•

ANALOGUE INTERFACE

Allows for the control of the rectifier with an analogue PLC.

•

•

MULTI-TOWER CONNECTION

This function is available when rise and fall times faster than 1 second are critical for the production process. Done by a combination of software and a selection of electrical components. Recipe patterns can be followed by controlling the CPU to achieve a rise time and fall time of 1ms with no overshoot when using resistive loads.

•

•

SOLENOID

—

An optional installation accessory that can be used to segregate the incoming water flow of the system. Prevents condensation when the rectifier is not in operation. It is not available when using the integrated Water to Water Heat Exchanger.

—

•

ACCESORIES

Remote Control

Remote control REM8E, 24VDC / 24VAC

Remote control REM8 that includes analog/digital input and output ports REM8, 85-264VAC.

REMMTV

Portable equipment to adjust and perform functional tests of the CTRL and CPU cards for Vega.

RSM09A

Quasar and Vega simulator (with CPU090 and 4-line display).